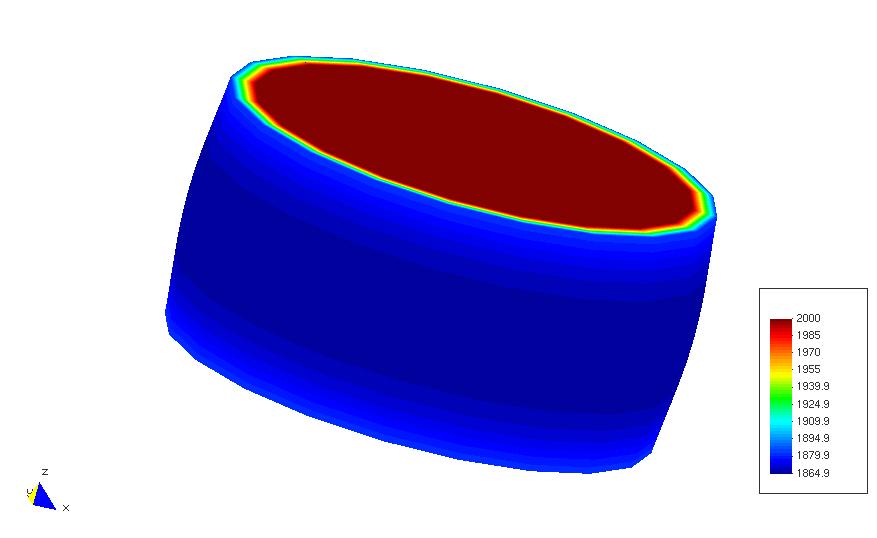

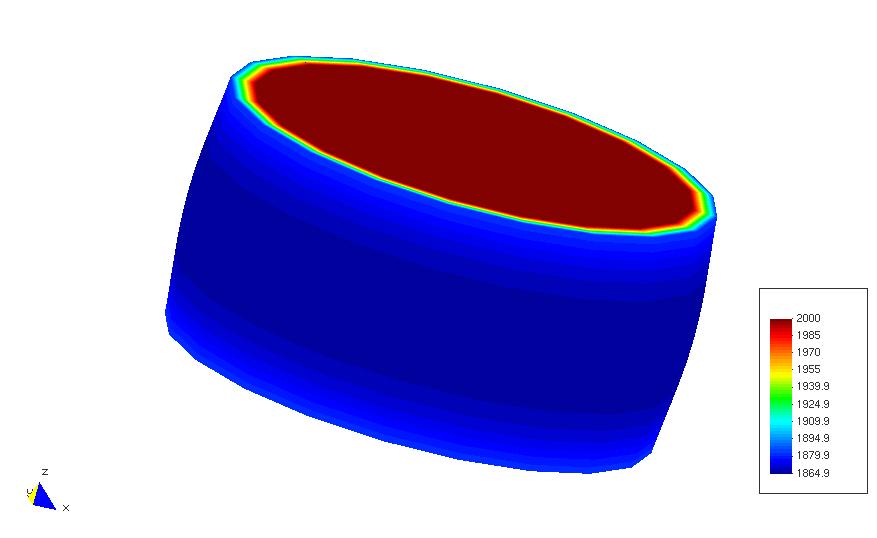

A hollow cylinder contains a hot fluid. The heat of the fluid is conducted over the wall of the cylinder to the outer radius. At the outer radius of the cylinder, the heat convects to the environment.

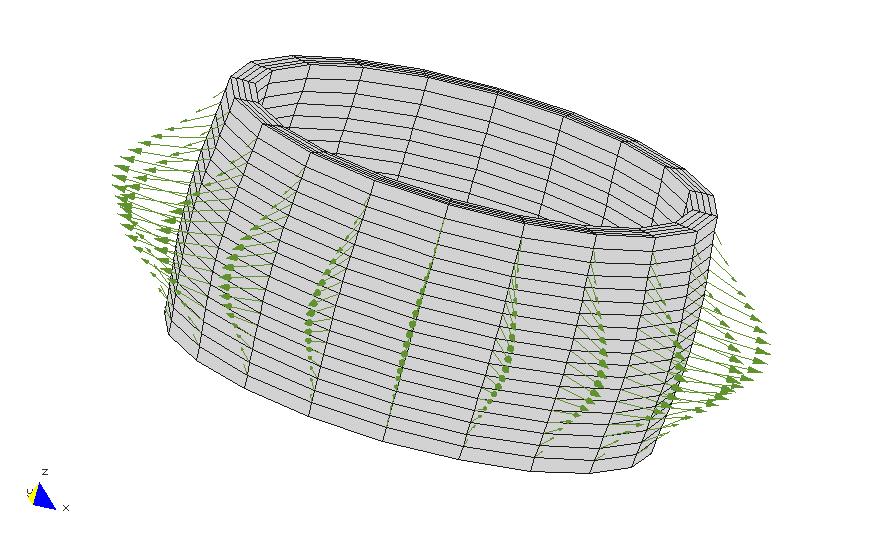

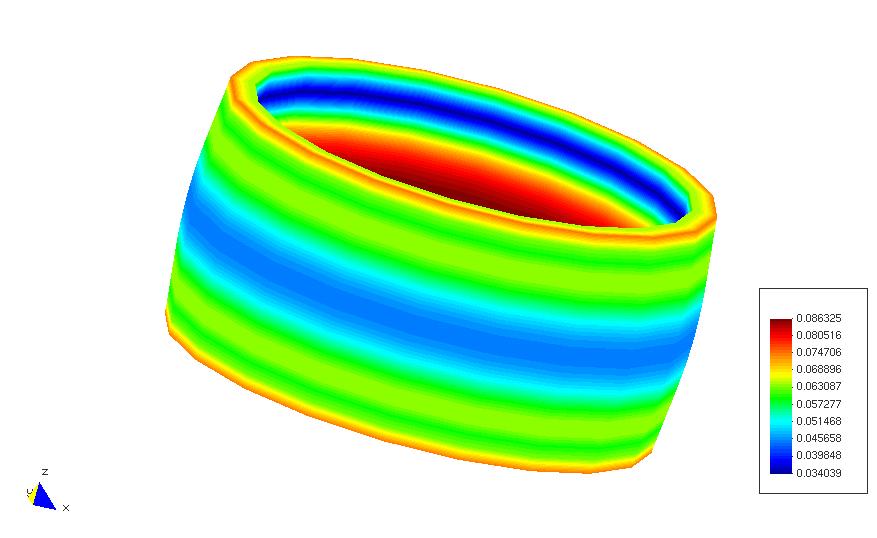

Because of this heating, the steel cylinder thermally expands. Since the cylinder is clamped at its top edge and lower edge, it buckles to enable the expansion. The large strains and rotations of material of the cylinder are accounted for by using a large deformation updated lagrange formulation. Von-Mises plasticity is used to model permanent deformations in the steel.

In the calculation, the thermal problem and stress problem are simultaneously solved. The first plot shows the calculated temperature distribution.

The velocity vectors are shown in the second plot below in the finite element mesh. It is clear that the cylinder is clamped at its edges, and buckles in its first mode.

In the third plot the plastic strains are shown, which result from the rather large deformations of the sphere.

Here is the Inputfile. The plots are made with the GID pre-post processor.